In today’s modern railway transport, speed, axle loads, and the variability of wagons demand advanced technologies that ensure both safety and performance.

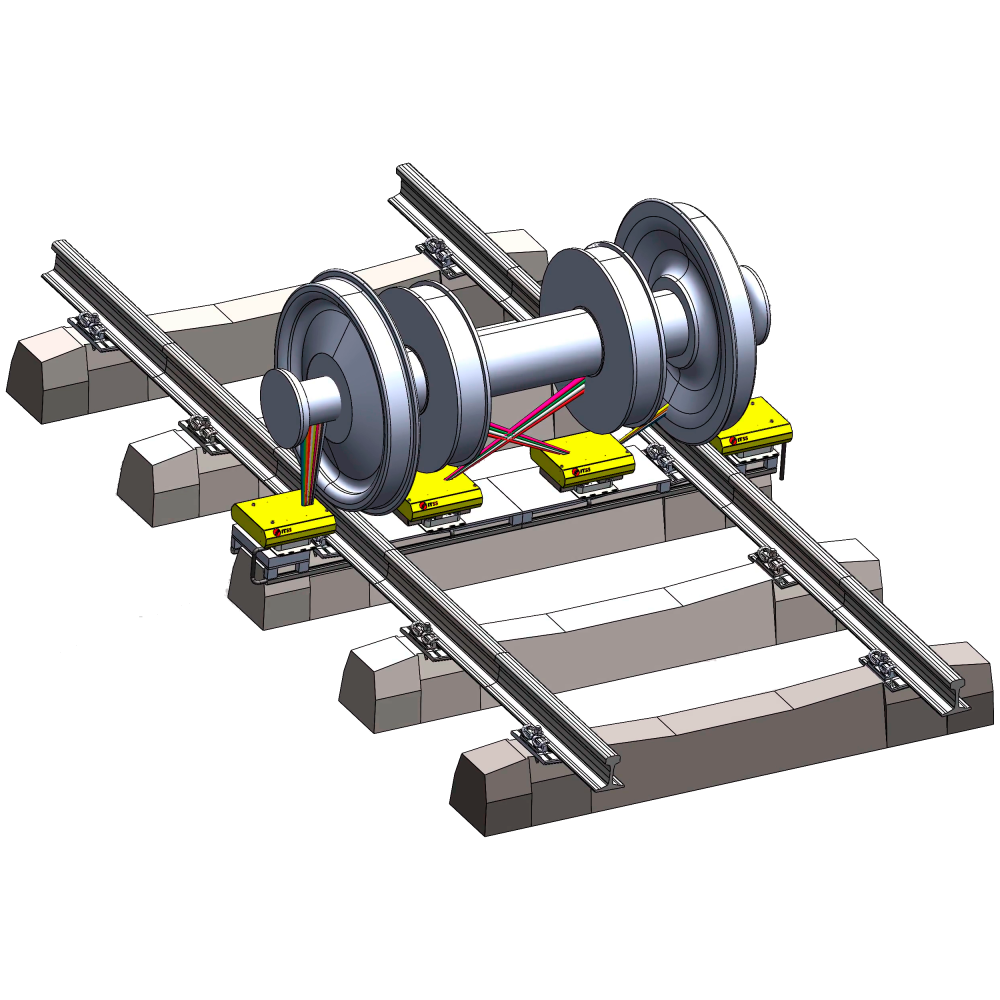

Pegasus Genius, the evolution of the original Pegasus system developed by ITSS, represents a new era in hotbox detection, eliminating the need for hollow sleepers, allowing for faster and more adaptable installation in any environment.

Pegasus Genius not only adheres to the strict safety and efficiency standards of the original Pegasus but also introduces significant enhancements, making it even more reliable and easier to implement.

This advanced monitoring system is designed to detect overheated axle boxes and defective brakes with unparalleled precision.

Equipped with our exclusive patented vibration sensor technology, Pegasus Genius measures and analyzes vibrations caused by passing trains, preventing gradual damage that might go unnoticed until it’s too late.

This unique feature allows for early intervention, reducing risks and operational costs for railway operators.

General Technical Data:

- Operating System: Linux

- Vibration Protection and Threshold Monitoring IVM: (Patent EP 1772342)

- Measurement of all types of standard axle bearings

- Continuous measurement of the entire bearing surface

- Enhanced safety through redundant detection, using up to 10 independent beams

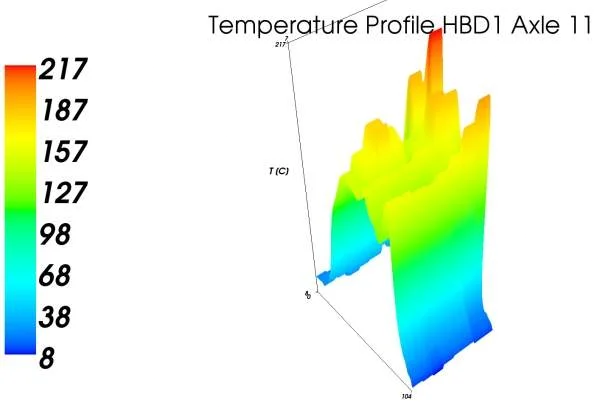

- 3D thermal image with approx. 7200 scanned points at 500 km/h

- Applicable Standards:

- TSI Interoperability of the Trans-European High-Speed Railway System (Directive 2006/860/EC)

- EN 55011:98 + A1:99 + A2:02, Class B (Emission Test)

- EN 50121-4:00 (EMC)

- EN 50125-3

- Developed according to EN 50128

- Modular System Design:

- Sensor modules can be replaced within minutes

- No adjustment needed after replacement

- Alignment without dismantling system components

- No hollow sleeper installation: Greater versatility and easier installation on any track without structural modifications.

Scanner Specifications:

- Scanner Connection: Ethernet 100 MB

- Scanner Versions: 4/8/10 beams

- Up to 32 HBD/HWD scanners can be connected to a single electronic system alongside the track

- Maximum Number of Axles: 3000

- Data Link Format: TCP/IP, various protocols (XML, OPC, etc.)

- Automatic identification of locomotives, wagons, and train compositions

HWD (Hot Wheel Detector):

- Thermal imaging of brakes

- Maximum train speed: 500 km/h

- Thermal image temperature range: 50°C – 650°C

- Temperature resolution: +/- 1°C

- Accuracy (repeated measurements): +/- 10°C

- Sensor width for rim and disc brakes: 50 – 140 mm

- Redundant auto calibration (RAC) and self-monitoring

- Effective range: -40°C to +70°C

- Scans rim and disc brakes

HABD (Hot Axle Box Detector):

- Thermal imaging of axle bearings

- Maximum train speed: 500 km/h

- Thermal image temperature range: 0°C – 200°C

- Temperature resolution: +/- 1°C

- Accuracy (repeated measurements): +/- 1°C

- Sensor width:

- 60 – 140 mm (10 beams)

- 50 – 120 mm (8 beams)

- 25 – 60 mm (4 beams)

- Redundant auto calibration (RAC) and self-monitoring

- Effective range: -40°C to +70°C

- Scans all types of axle bearings